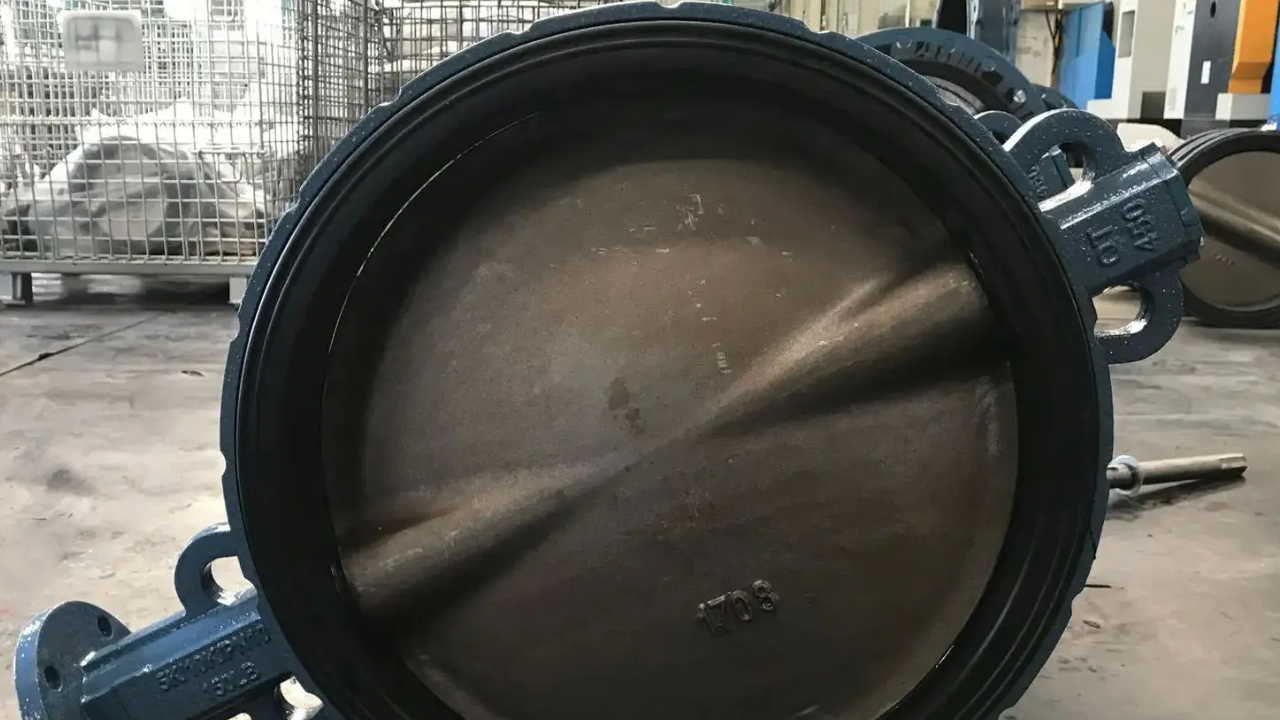

A variation on butterfly valves, lug-type valves include threaded lugs on the valve body that provide a different method of fluid control. Without having to interrupt the pipeline completely, these threaded lugs allow for a semi-permanent connection between flanges during secure installation. Lug-type valves are widely used in a variety of industries, including chemical processing, HVAC systems, and water treatment. They are renowned for their adaptability.

Because of their unique design, which makes installation and maintenance easier, they are the recommended option in situations when regular valve replacement or servicing is required. Fast attachment is made possible by the threaded lugs, which guarantee a strong and dependable connection. The regulation of liquid and gas flow is an essential function of lug valves, which demonstrate their effectiveness and usefulness in a range of industrial environments.

Can Lug-type Butterfly Valves Be Automated with Actuators?

Yes, actuators make it simple to automate lug-type butterfly valves. Precise valve location and functioning are made possible by actuators, which offer remote control and automation capabilities. This allows for integration into automated processes and improves efficiency. Actuated lug-type butterfly valves are frequently employed in a wide range of industrial settings where remote control and operation are crucial for process optimization and system dependability.

Materials Frequently Utilized to Build Lug-style Butterfly Valves

The materials that are frequently used to make lug-type butterfly valves, investigate their characteristics, benefits, and uses.

Iron Casting

A common and conventional material for making lug-style butterfly valves is cast iron. It is appropriate for handling a variety of fluids, such as water, air, and non-corrosive liquids, because of its exceptional strength and durability. Cast iron valves are frequently used in processes related to general industrial operations and HVAC systems, where robustness and cost-effectiveness are important factors.

Ferrous Ductile

Another common option for lug-style butterfly valves is ductile iron, which is an alloy of iron and trace amounts of magnesium. It is more resilient to cracks and fractures while maintaining the strength of cast iron thanks to its increased ductility. Applications needing increased durability, such as municipal water distribution systems and water treatment plants, are suited for ductile iron valves.

Stainless Steel

Stainless steel is well known for being incredibly strong and resistant to corrosion. Stainless steel lug-type butterfly valves are perfect for settings or applications where corrosive fluids are present. Common grades of stainless steel that are utilized are 304 and 316. 316 has a better resistance to corrosion, which makes it ideal for use in offshore applications, the food and beverage industry, and chemical processing.

Steel with Carbon Content

Because of its strength and adaptability, carbon steel is a valuable material for lug-style butterfly valves. Applications where a reasonable level of corrosion resistance is acceptable frequently employ it. Power plants, the oil and gas sector, and general-purpose industrial processes all use carbon steel valves.

Aluminum

Because it is lightweight and resistant to corrosion, aluminum is a good material option for lug-type butterfly valves in applications where weight is important, like portable fluid control systems or aircraft. Aluminum valves are not as widely utilized as other materials, but they have advantages in some applications where their special qualities come in handy.

Polyvinyl chloride, or PVC

Thermoplastic polymer PVC is frequently utilized in the manufacturing of lug-style butterfly valves, which are designed to manage non-corrosive fluids like water. PVC valves are renowned for being inexpensive, lightweight, and resistant to corrosion from chemicals. They are frequently found in irrigation, plumbing, and water treatment systems.

Chlorinated Polyvinyl Chloride, or CPVC

With more chlorine added for better heat resistance, CPVC is an upgraded variant of PVC. CPVC lug-type butterfly valves are appropriate for situations involving elevated temperatures, like hot water systems, chemical processing, and industrial settings needing resilience to corrosive substances.

Buna-N, also known as nitrile

Synthetic rubbers like nitrile have strong resistance to chemicals, fuels, and lubricants. Oil and hydrocarbon-related applications are a good fit for lug-style butterfly valves with nitrile seats. Petrochemical facilities, fuel handling systems, and the oil and gas sector are among the industries that use these valves.

Conclusion

The performance and appropriateness of lug-type butterfly valves for various applications are greatly influenced by the materials used in their fabrication. Every material has a different set of benefits, ranging from cutting-edge polymers and alloys to more conventional options like cast iron and stainless steel. Because of the material’s adaptability, lug-type butterfly valves can be customized to match particular industry needs, offering dependable and effective fluid control solutions.