The material used in the molding process requires a curing stage while the material is still in the mold, which is one of the key ways that reaction molding procedures differ from traditional injection molding. Two thermosetting polymers that react and cure when combined are the basis of reaction injection molding. Reaction injection molding has a unique benefit.

Reaction injection molding necessitates more time and expensive molding materials. The liquid formulation is typically supplied into a reservoir, heated, mixed, and then put into a mold in a prepared chamber where it cools and solidifies. The liquid formulation is typically supplied into a reservoir, heated, mixed, and then put into a mold.

Multiple pieces can be produced on a single typical injection molding machine thanks to the removable mold, which is built using a different method. The thing that has already hardened is taken out and put in a location where it will continue to harden. The RIM technique involves metering a liquid monomer or prepolymer in a specific ratio into the mixing head for mixing.

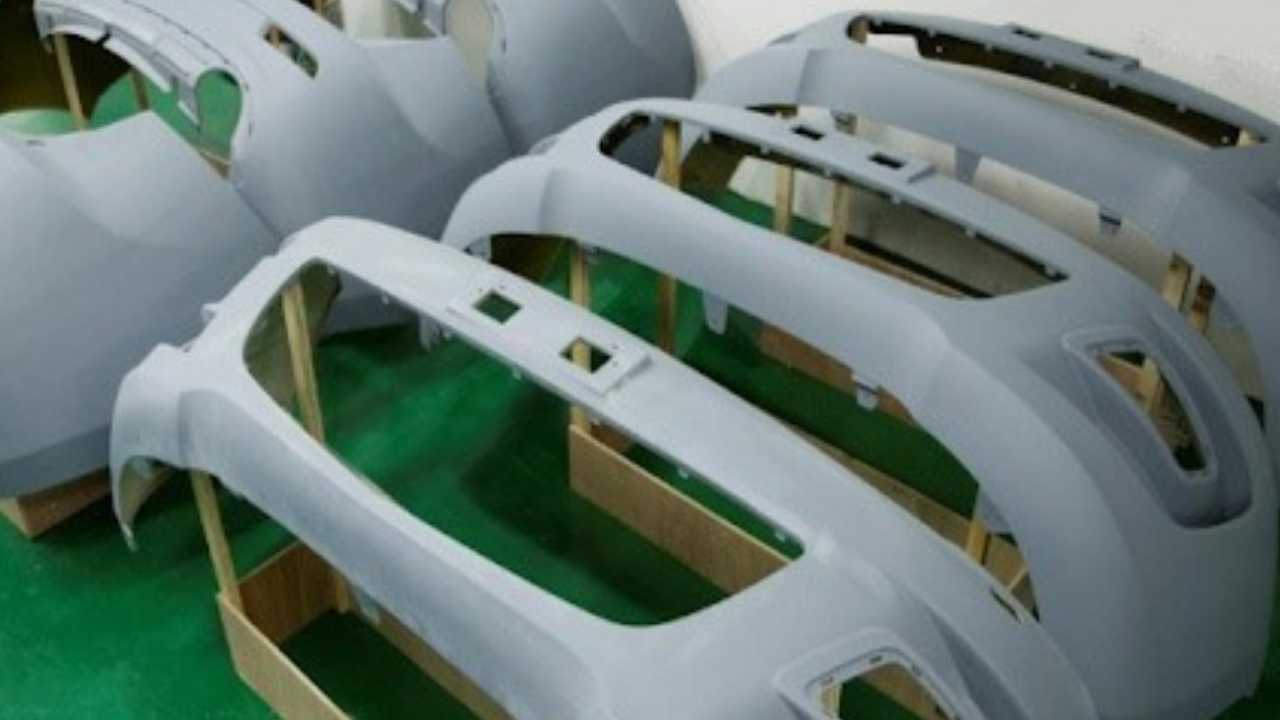

Process of Reaction Injection Molding

Low-viscosity liquid polymers are used in the reaction injection molding process. These polymers thicken and expand as a result of numerous chemical processes. The polymers finally harden after being introduced into the heated medium. The thing that has already hardened is taken out and put in a location where it will continue to harden.

Multiple pieces can be produced on a single typical injection molding machine thanks to the removable mold, which is built using a different method. The steps in this procedure can be boiled down to these stages storage, measuring, mixing, mold filling, curing, ejecting, and post-processing.

Storage

Two separate storage containers, often pressure vessels, are used to hold the RIM process employed in the two-component liquid at a specific temperature. When not forming, the stock liquid typically circulates constantly in the storage tank, heat exchanger, and mixing head at a low pressure of 0.2–0.3 MPa. The typical raw liquid temperature range for polyurethane is 20 to 40 °C, with a temperature control precision of 1 °C.

Measuring

The hydraulic system, which is made up of pumps, valves, and auxiliary components (piping for controlling liquid material and an oil circuit system for managing the distribution cylinder’s operation), typically consists of meters of two-component raw liquid. Additionally, the high and low-pressure conversion devices must be used when injecting to change the pressure to the level needed for the injection.

Mixing

In the RIM product molding process, both product quality and production capacity are mainly dependent on the mixing quality of the mixing head and multistream mix head, respectively. 10.34 to 20.68 MPa is the standard pressure range, which is used to get a better mixing effect.

Filling Of the Mold

The rapid flow of the material distinguishes the response of injection material filling. Because of this, the original liquid’s viscosity shouldn’t be too high; for instance, while filling a mold, a polyurethane mixture has a viscosity of roughly 0.1 Pa.s. There are just two crucial process variables once the material system and the mold have been selected, namely the mold filling time and the raw material temperature.

Curing

After being injected into the mold cavity, the two-component polyurethane mixture has high reactivity and may be cured and formed in a very short time. The molded material cures from the inside out because of the poor thermal conductivity of plastic, which prevents a significant amount of reaction heat from dissipating over time. As a result, the internal temperature of the molded material is significantly greater than the surface temperature.

Conclusion

High-strength packaging foams and lightweight parts for automobiles can both be made using the reaction injection molding technique. For unusual geometries (such as oversized pieces with variable wall thickness) or over-molding and insert molding. RIM may be preferable over injection molding 3ERP offers many services for reaction injection molding.