The construction of tunnels and subways requires meticulous planning and the use of materials that can withstand the unique challenges posed by underground environments. Among the critical components that contribute to the success of such projects is ASTM A252, a standard specification for welded and seamless steel pipe piles. This article explores the indispensable role of astm a252 in underground construction, specifically focusing on its applications in tunnels and subways.

The Unseen Challenge: Underground Construction

Constructing tunnels and subways presents an array of challenges, from geological considerations to the need for materials that can withstand the dynamic forces and environmental conditions inherent to subterranean spaces. ASTM A252 emerges as a crucial solution, providing the strength and durability required for the successful completion of underground projects.

ASTM A252: A Foundation of Strength

Understanding ASTM A252 Specifications

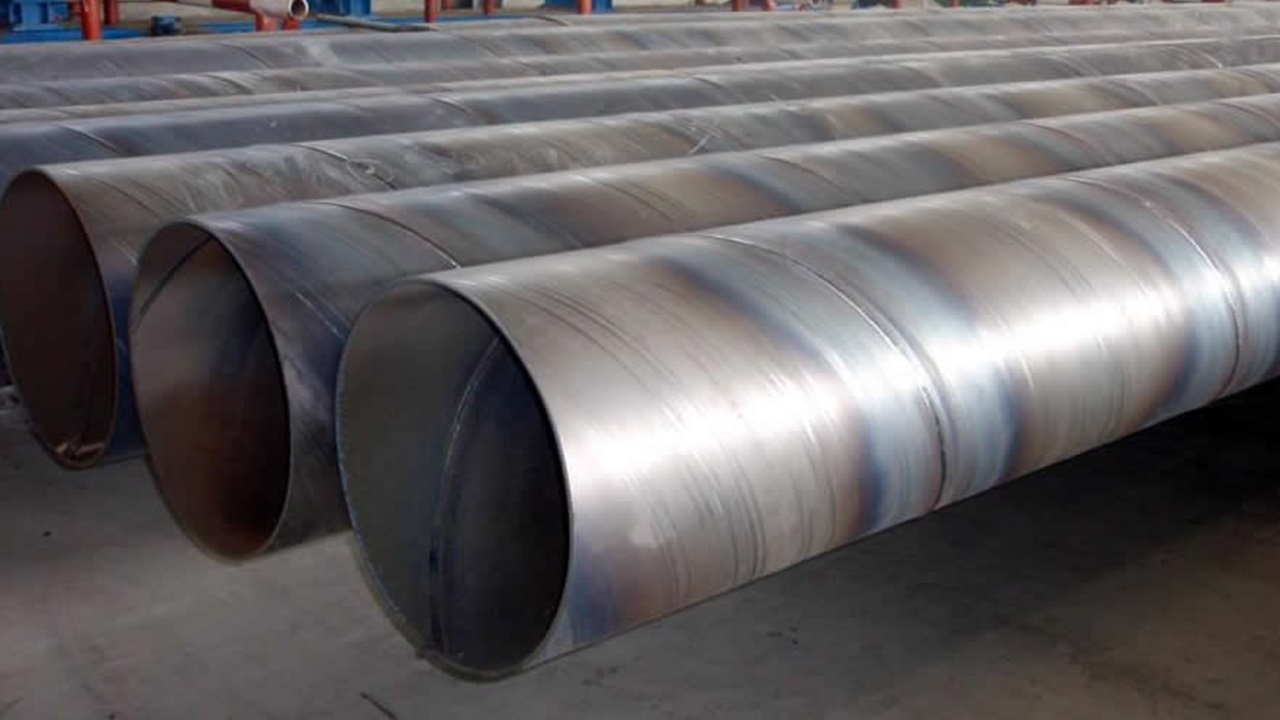

ASTM A252 lays down specifications for steel pipe piles, encompassing both welded and seamless options. The stringent requirements set by this standard ensure that the materials used in underground construction possess the necessary strength and resilience.

Grades and Applications

ASTM A252 offers different grades, each tailored to specific applications. Understanding these grades is vital, as they dictate the material’s suitability for different underground environments, considering factors like soil conditions and structural requirements.

ASTM A252 in Tunnel Construction: The Hidden Support

Tunnels, whether for transportation or utilities, demand materials that can provide structural support while resisting the unique challenges posed by the surrounding earth.

Load-Bearing Capabilities

ASTM A252’s focus on load-bearing capabilities makes it an ideal choice for tunnel construction. The material’s ability to withstand substantial loads is essential for ensuring the stability and safety of tunnels, especially in urban areas where infrastructure demands are high.

Resistance to Deformation

Underground spaces are subject to shifting and settling, which can exert immense pressure on the structures within. ASTM A252’s resistance to deformation is crucial in maintaining the integrity of tunnels over time, preventing issues such as subsidence.

ASTM A252 in Subway Infrastructure: A Pathway of Strength

Subways are intricate networks of tunnels that require robust materials to support the weight of trains, ensure passenger safety, and withstand the constant vibrations and stress associated with daily operations.

Vibration Resistance

Subways generate vibrations due to the movement of trains, and the materials used must be resistant to such forces. ASTM A252’s ability to withstand vibrations contributes to the longevity of subway structures, reducing the need for frequent maintenance and ensuring passenger safety.

Durability in Challenging Environments

Subway tunnels often encounter challenging environmental conditions, including high humidity and potential exposure to corrosive elements. ASTM A252’s durability and corrosion resistance make it an excellent choice for subway construction, ensuring a prolonged service life for the infrastructure.

Conclusion

In conclusion, ASTM A252 stands as an indispensable material in the realm of underground construction, specifically in the creation of tunnels and subways. Its ability to provide structural support, resist deformation, withstand vibrations, and maintain durability in challenging environments makes it a preferred choice for engineers and builders navigating the complexities of constructing below the surface. For those embarking on underground projects, understanding the role of ASTM A252 is essential in ensuring the success and longevity of the infrastructure.